Steel

Efficiently converting iron ore into usable pieces of steel requires precision at each stage in the process. KEYENCE sensors provide measurement and inspection solutions to every facet of the steel industry - including red hot metal, cold rolling, and forming. Check out some of the solutions our sensors provide below.

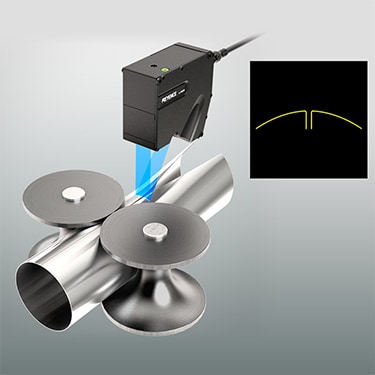

Tracking the position and height of each edge prior to welding helps to minimize defects that could negatively impact weld performance.

2D/3D Laser Profiler

LJ-X8000 series

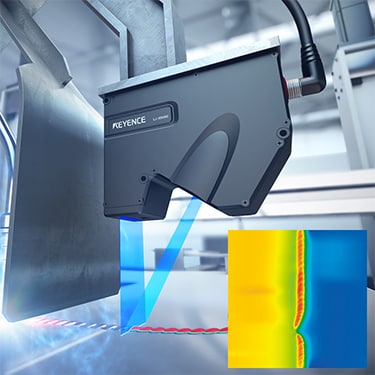

Catch welding defects such as pits, melting, or spatter with 2D or 3D inspection using laser profilers. The LJ-X8000 is unaffected by the colour of the weld, so it can reliably inspect any weld.

2D/3D Laser Profiler

LJ-X8000 series

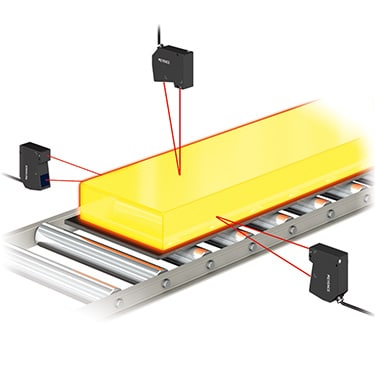

Red hot slabs can be measured during processing to minimize rework. The LK-G3000's long range enables you to place the sensor up to 1m away from the heat source while maintaining accurate measurements.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

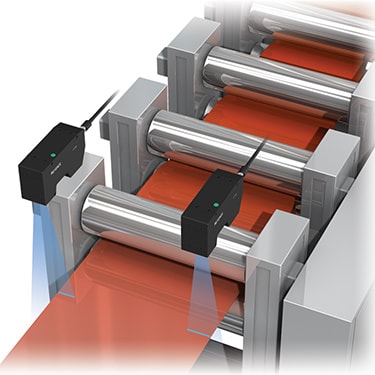

Stably detect the edge position of red hot steel plates using a blue laser profiler. Easily detect defects without touching the sheet.

2D/3D Laser Profiler

LJ-X8000 series