Case Studies Customer Testimonials — Thickness

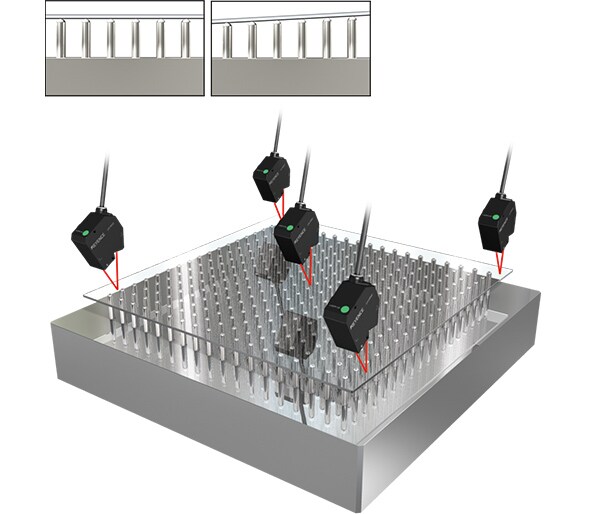

Case 1: Thickness Measurement of Glass

| Industry | Semiconductors, LCD Industry |

|---|---|

| Application | Thickness measurement of glass |

| Model Adopted | LK-G5000 Series |

We used to perform thickness measurement of glass using laser displacement sensors from another company. Tracking errors occurred with patterned surfaces, and we couldn't seem to improve inspection cycle times. Using KEYENCE's LK Series of laser displacement sensor, we were able to eliminate tracking errors and improve inspection cycle times.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

Tracking errors occur because of differences in the reflectance of glass surfaces and some patterned surfaces. The LK Series laser displacement sensors offer high-speed control of emission times and emission power so the received light is constantly optimised for the surface. This makes it possible to minimise the impact of tracking errors.

KEYENCE

KEYENCE

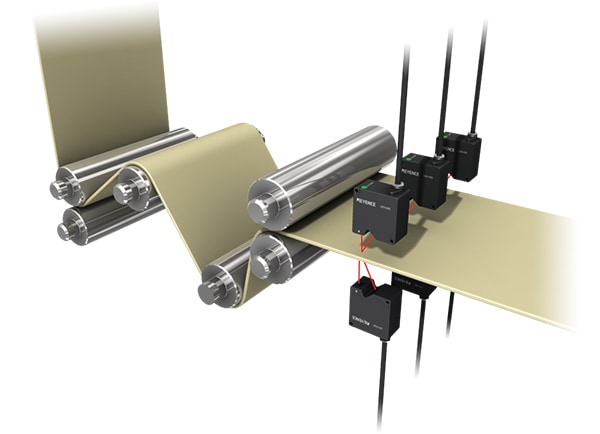

Case 2: Thickness Measurement of Uncut Noodle Sheets

| Industry | Food Industry |

|---|---|

| Application | Thickness measurement of uncut noodle sheets |

| Model Adopted | LK-G5000 Series |

For inspecting the thickness of noodles, we used a hand micrometer. Our results varied greatly, especially for soft noodles, due to different contact pressure during measurement. Using KEYENCE's LK Series of laser displacement sensor, we were able to handle thickness measurements in-line. And because the LK Series utilises non-contact measurement, we were able to resolve the issue of operator error.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

Our devices have often been used for noodle thickness measurement. During noodle production, flour is a constant presence in the air. However, With the LK Series of laser displacement sensors, stable measurement is possible with no influence from flour thanks to a built-in median filter that cancels out any unexpected values.

KEYENCE

KEYENCE

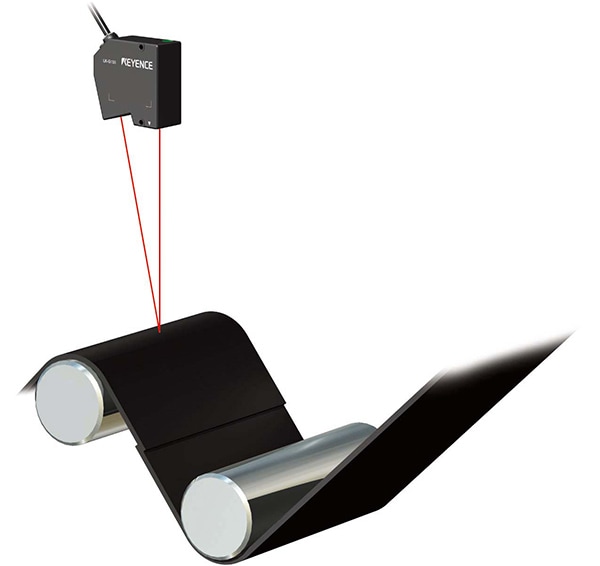

Case 3: Thickness Measurement of Rubber Sheets

| Industry | Resin and Rubber Industry |

|---|---|

| Application | Thickness Measurement of Rubber Sheets |

| Model Adopted | LK-G5000 Series |

We previously performed thickness measurement of rubber sheets in-line using conventional laser displacement sensors. However, the sensors could not support stricter product tolerances, so we tried out LK Series laser displacement sensors from KEYENCE. The LK Series handled the stricter tolerances and helped to us to resolve our issue measurement variations due to the surface roughness.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

The LK Series of laser displacement sensor offers a sampling speed of 392 kHz, the fastest in the world. The ability to average a large amount of data obtained under such high sampling speeds allows for stable thickness measurement even with in-line measurement.

KEYENCE

KEYENCE

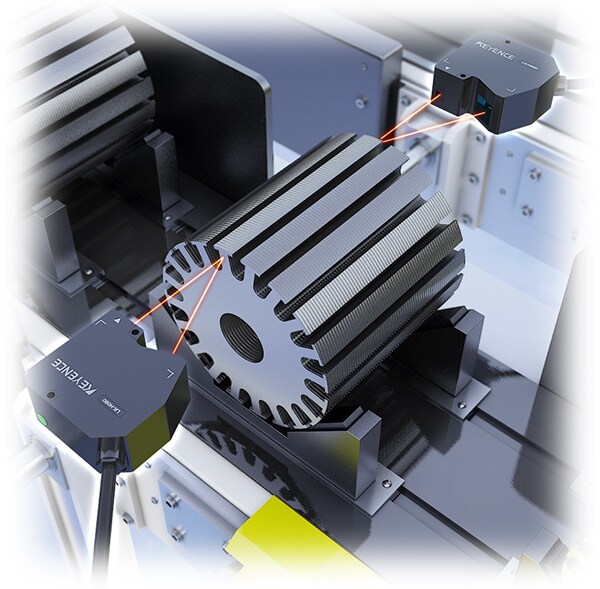

Case 4: Thickness Measurement of Laminated Layers on Motor Core

| Industry | Transport/Metals Industry |

|---|---|

| Application | Thickness Measurement of Laminated Layers on Motor Core |

| Model Adopted | LK-G5000 Series |

For laminated motor cores, device performance changes depending on the number of laminated layers. For this reason, we first visually checked whether the specified number of core layers had been set. By using KEYENCE's LK Series of laser displacement sensor for in-line thickness measurement, we were able to inspect our products automatically.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

For thickness measurement, micron scale accuracies are required for determining whether the number of cores is within the specified range. LK Series laser displacement sensors employ an optical design that reduces the influence of surface roughness and utilises proprietary components to enable high-accuracy measurement regardless of the target.

KEYENCE

KEYENCE

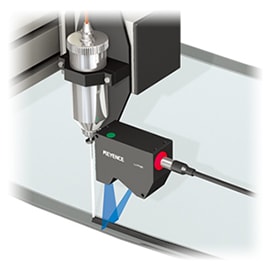

Case 5: Thickness Measurement of Glass Panel Sealant

| Industry | Transport/Metals Industry |

|---|---|

| Application | Thickness Measurement of Glass Panel Sealant |

| Model Adopted | LJ-V Series |

A camera was used to inspect glass panel sealant application. The camera allowed us to perform coating crack inspections, but we also needed to inspect the inclination of the sealant. For this, we adopted the LJ Series 2D laser displacement sensor from KEYENCE. With the sensor head fixed to the dispenser, we were able to not only look at coating cracks but also measure the thickness, width, and cross-sectional area of the sealant.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

The LJ Series 2D laser displacement sensor boasts the fastest sampling speed in the world. Even when controlling a dispenser at high speed, it is possible to measure the interposed pitch and thus prevent sealing failures.

KEYENCE

KEYENCE