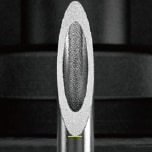

Key inspection points

The inspection tools necessary for connector inspections have been included as a package, which enables easy configuration of settings without any calculations required. It is possible to perform even more highly accurate inspections by using the 21 megapixel camera.