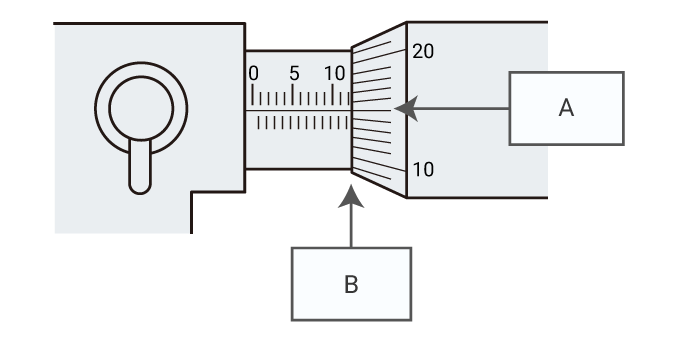

- A

- The thimble scale shows "0.15."

- B

- The thimble scale exceeds "12.0 mm."

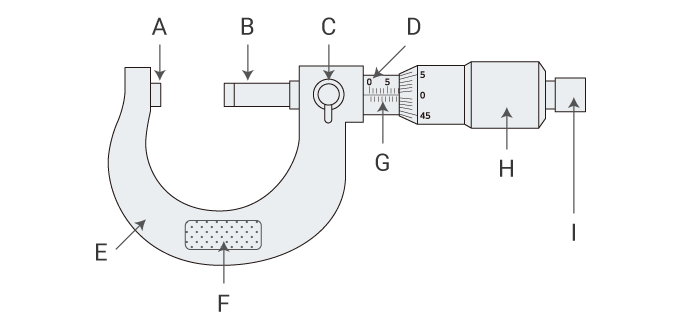

Micrometers

Overview

A micrometer is a tool that measures the size of a target by enclosing it. Some models are even able to perform measurements in units of 1 μm. Unlike hand calipers, micrometers adhere to Abbe’s principle, which enables them to perform more accurate measurements.

In general, the term "micrometer" refers to outside micrometers. A variety of other types of micrometers also exist according to different measurement applications. Examples include inside micrometers, bore micrometers, tube micrometers, and depth micrometers. The measurable range differs every 25 mm—such as 0 to 25 mm and 25 to 50 mm—depending on the size of the frame, so using a micrometer that matches the target is necessary. Recently, digital micrometers have become incredibly popular.

Abbe’s principle states that, "In order to improve measurement accuracy, the measurement target and the scale of the measuring instrument must be placed in a collinear fashion in the measurement direction." With micrometers, the scale and the measurement position are collinear, so these instruments follow Abbe’s principle. As such, micrometers can be said to have high measurement accuracy.

Construction and Applications

- A

- Anvil

- B

- Spindle

- C

- Clamp

- D

- Sleeve

- E

- Frame

- F

- Heat-resistant plate

- G

- Scale

- H

- Thimble

- I

- Ratchet stop

- Place the target between the anvil and the spindle, and then turn the thimble to lock the target between the two surfaces.

How to Use a Micrometer

- Before measurement, wipe down the anvil and spindle surfaces with a clean cloth. This removes dirt and dust from the surfaces, which enables accurate measurements.

- To hold the micrometer, hold the heat-resistant plate on the frame with the thumb and index finger on your left hand, and pinch the thimble between the thumb and index finger on your right hand.

- Grip the target between the anvil and the spindle, turn the ratchet stop until it slips, and then read the value.

- Read the value from the main scale on the sleeve and the scale on the thimble. Use the line on the right edge of the sleeve to read the value in units of 0.5 mm. You can then use the scale at which the centre line on the thimble (scale) lines up to read the value in units of 0.01 mm.

12.0 + 0.15 = 12.15 mm

Handling Precautions

- Use a gauge block or a dedicated gauge to calibrate a micrometer. In order to perform accurate measurements, the anvil surface must always be flat. After multiple measurements are performed, the surface may become no longer flat due to wear and the accumulation of dirt. Therefore, periodically use a part known as an optical flat to check whether the surface is flat according to the displayed Newton's rings.

- When measuring a metal target and when performing calibration with a gauge block, exercise caution with respect to thermal expansion. Whenever possible, avoid holding metal with bare hands, or use gloves that do not transmit heat and are designed for precision work.

- The calibration interval of micrometers is 3 months to 1 year.

- Measurement System Types and CharacteristicsVernier Calipers/Height Gauges (Depth Gauges)

- Measurement System Types and CharacteristicsProfile Projectors