Selecting by Application

Length Measurement

Rulers, tape measures, and gauge blocks are commonly used to measure length at manufacturing sites. Long scales are used for targets that are a few metres in length. To perform more precise measurements, instruments such as Vernier calipers, dial gauges, and micrometers are used.

Angle Measurement

Half circle protractors are useful for measurements in units of degrees. Bevel protractors and optical comparators are used for measurements in units of arcminutes. A measuring instrument known as a sine bar is available for more precise measurements in units of arcseconds. Measurements in units of arcseconds can also be performed by using an angle gauge or an autocollimator.

Engineer's squares and squareness testers are available tools for checking perpendicularity.

Bore Diameter Measurement

Vernier calipers are used to measure the diameter of holes in objects. There are also dedicated inner diameter measuring instruments.

Tube micrometers, cylinder gauges, small diameter measuring instruments, and plug gauges are used to measure ring-shaped targets with large diameters. Electronic micrometers and air micrometers are used to perform more precise measurements.

Measuring instruments such as optical comparators, industrial microscopes, and image dimension measurement systems are useful when precise optical measurements are needed.

Coordinate Measurement

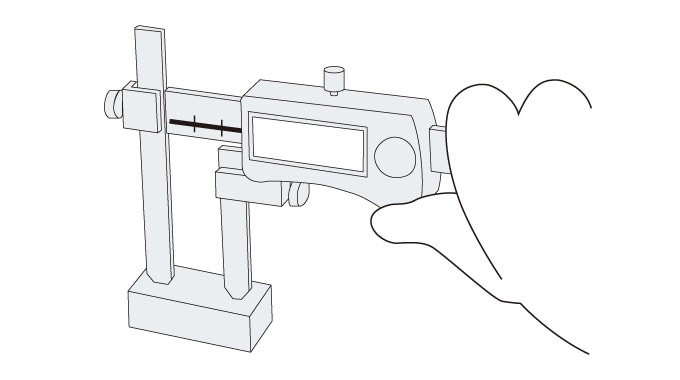

Off-centre Vernier calipers, hole pitch gauges, height gauges, and pin gauges are used to measure coordinates such as the positions of holes in workpieces.

Measuring instruments such as optical comparators, industrial microscopes, 2D/3D measuring instruments, and image dimension measurement systems are useful if precise optical measurements are needed. Standard optical interferometers are used for ultra-precise measurements such as for semiconductors.

- Selecting a Measurement SystemSelecting by Measurement Environment

- Selecting a Measurement SystemSelecting by Measurement Speed