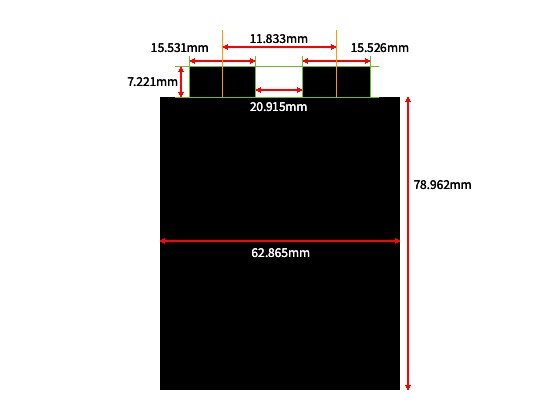

Dimensional measurement of laminated packages

-

Industry:

- Automotive, Plastics, Films/Sheets

-

Products:

- Optical Metrology Systems

After lamination, the outer dimensions and the positions of positive and negative electrodes are measured. Positive and negative electrodes in incorrect positions may short-circuit, failing to ensure safety. They also may fail to charge and discharge as expected. As a very important measurement item, their positions commonly undergo offline sampling inspection in addition to 100% inline inspection. Many items need to be measured, so the IM Series is very effective as it can measure multiple measurement points instantaneously. Higher measurement speed leads to more efficient production lines, increasing the number of samples that can be taken for sampling inspection.