High-Performance Micro Static Eliminator

SJ-M series

High-Performance Micro Static Eliminator SJ-M series

Ultra-Small Integrated Sensing Ionizer

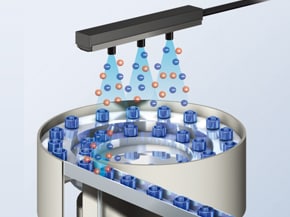

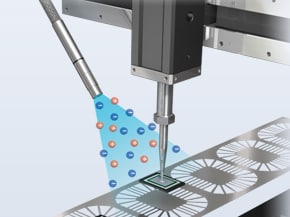

Eliminate static electricity for a target area of 200 mm at an installation distance of up to 200 mm. The SJ-M Series boasts an ultra-compact ⌀10 mm static electricity elimination head suitable for installations within equipment or in narrow spaces.

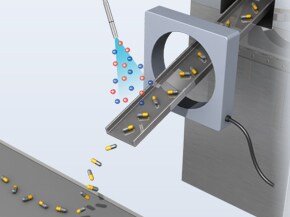

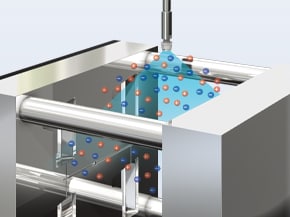

Applications

Features

Ultra-small Static Elimination Head Has No Limitation on Installation Space

Since the SJ-M Series provides a direct static elimination structure that directs the ion generation point at the tip of the head, it allows for high-speed and high-precision static elimination where it is needed most.

Static Elimination over Areas at Distances of 1 m or More Using a ⌀12 mm Head

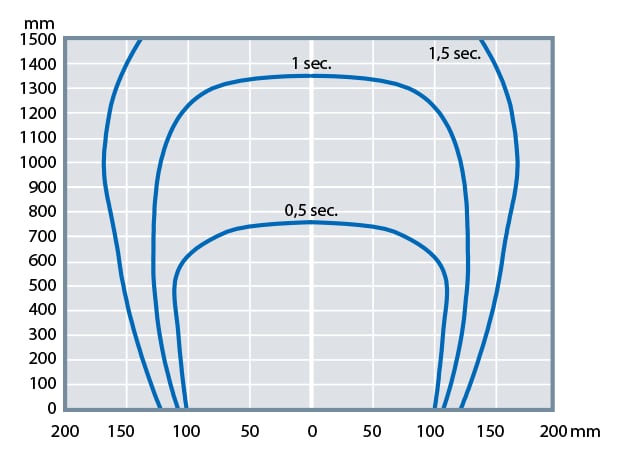

Static elimination range and time (typical) (Applied pressure of 0.5 MPa)

Remove static electricity from an area as large as 600 × 1500 mm using just a compact head. Eliminate static from more than 1 m away in under 1 second. Use branching to remove static electricity from inside devices.

Varied Lineup

Choose from spot/nozzle models as well as ultra-compact bar models. Take advantage of focused, reliable elimination of static and dust in narrow spaces or throughout a limited space. Silicone probes are also available for use in environments where metal contamination is a concern.

Ultra-fine Nozzle Standard probe type

With its ultra-fine nozzle of ø12 mm, a 0.5 MPa high-pressure air purge is possible.

Ultra-fine Nozzle C.A.B.probe type

Five times less maintenance than conventional models.

Ultra-small Bar C.A.B.probe type

Innovative design significantly reduces the need for cleaning/maintenance.

Ultra-small Bar Silicon probe type

Suitable for environments in which metal contamination must be avoided.